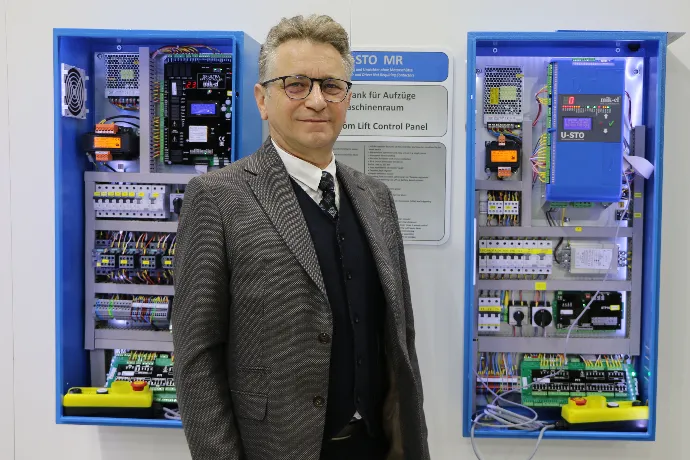

MIK-EL LAUNCHES ITS MINI U-STO

HABER ASANSÖRÜ (GERMANY) — Mik-el Elektronik made a splash with its new products introduced at the Interlift Fair held in Augsburg, Germany. At the fair, "Mini U-STO", the smaller size of the integrated elevator control and driver called U-STO, was exhibited for the first time at Interlift, while the "Mobile Smart Handheld Terminal Application" was presented to the users.

Mik-el Elektronik, one of the most rooted control system manufacturers in the Turkish elevator market, and also gaining an important place in the sector with its many complementary products such as smart floor and car button boards and car position sensors, showcased its new products at the Interlift Fair held in Germany.

Answering the questions of Haber Asansörü at the Interlift Fair, Mik-el Elektronik Board Member and General Manager Nihat Güven announced that "Mini U-STO" will enter mass production soon and said that they are preparing for promotion.

CREATED OPPORTUNITY IN RESPECTABILITY

Making evaluations about Interlift Fair, Güven said:

“This year's Interlift has been much quieter than the previous ones. Many participants, including important companies, preferred not to take part in this fair. However, we can say that this situation created an opportunity for us to be noticed. Even though the number of visitors is below the usual level, we had the opportunity to have more effective conversations with the visitors.”

THERE IS STILL TIME FOR HIGH-SPEED ELEVATORS

Saying that they do not have significant differences with their global competitors in terms of technology level, Güven said, “However, technologies are used differently for target markets, of course. For example, the preferred -destination control- control method for very high stops, very fast and 4/6/6 lifts is not a priority for us for now. We need to use our R&D resources correctly and efficiently in line with our goals.”

Emphasizing that they have a sensitive approach to R&D studies, Güven said, “As the first company that brought this technology to the sector about 35 years ago, we have always given importance to R&D studies. We are able to develop products to meet the legislation and local demands of different markets, primarily the European market. In this way, we have a range of products suitable not only for Europe and the Middle East, but also for Asian and South American markets, and they are in constant development.”

HIGH CAPACITY PRODUCTION

“We have a production capacity of more than 10 thousand integrated elevator control/driver devices, more than 3 thousand elevator control panels, over 4 thousand elevator control card sets and a large number of accessory products such as smart button boards, car position sensors,” Güven said. line, high-definition optical quality control system, wave soldering system, manual soldering stations, many automatic test setups.

“WE HAVE BEEN A RELIABLE BRAND IN THE WORLD”

Guven stated that Mik-el Elektronik, which was established in 1988, is the first microprocessor-based electronic elevator control system manufacturer in Turkey to take place in the sector and said, "We have produced modern products by closely following the technology and constantly renewing the product portfolio. In addition to this, we have become a reliable brand with customers not only in Turkey but also in many different parts of the world, with our effective sales and after-sales support services.”

Talking about Mik-el Elektronik's service policy and development processes, Güven said, "Our services begin with our effective sales team, who aim to choose the right product in line with the customer's needs. It then continues with our production department, which includes strict quality control and traceability. At the last stage, our after-sales technical support unit provides our customers with a fast and effective commissioning and troubleshooting service.

MİK-EL ELECTRONICS SALES MANAGER EMRAH TERZAN: “OUR MINI U-STO PRODUCT SUPPORTS BETWEEN 4-7.5 KW, UP TO 1.6 M/S”

Mik-el Elektronik Sales Manager Emrah Terzan, who gave information about the new integrated elevator control system "Mini U-STO" exhibited at the fair, reminded that the compact structure of the "U-STO", which was introduced to the market before, was placed in a thinner body. Providing information about the technical details of the product, Terzan said:

“With Mini U-STO, it is a product that will serve elevators between 4-7.5 kW and up to 1.6 m/s cabin speed. Thanks to its compact structure, it enables the control panels to become smaller without sacrificing performance. Thus, we offer a very suitable solution for home lifts, which we call homelift, and modernization projects with space shortages.”

DIRECT EXPORT TO 30 COUNTRIES

Stating that they provide direct service to many customers in approximately 30 countries, Terzan said:

“Our products reach many more countries indirectly besides these countries. In order to protect and develop our portfolio, we first try to keep our relations with our customers warm. Customers who can reach us whenever they need, are happy and share their satisfaction with the companies around them, are more important than the most effective promotion for us to develop our export portfolio. We are also trying to provide our technical support service at the highest level.”

As the epidemic started to ease, we took our place in Elevator Istanbul, which was postponed to March 2022, and Interlift, which was postponed to April 2022, which are among the most important events of the industry. We had the opportunity to meet face-to-face with many new prospects and existing customers. These fairs are among the most beneficial events in terms of improving our targets in domestic and foreign markets.”

DESPITE THE PANDEMIC, OUR PORTFOLIO EXPANDED

Emphasizing that the pandemic period created various obstacles to the realization of sectoral organizations, Terzan said, "Even during this period, we managed to improve our business volume with some of our existing customers and add some new export customers to our portfolio."

Terzan mentioned that they have export customers with whom they have been working for more than 20 years and said, “This is a very satisfying picture for us in terms of the work we do. Of course, we certainly do not see this as a reason for complacency. On the contrary, we are aware that this will be sustainable by continuing to work hard and always being able to stay in warm contact with our customers.”

50 PERCENT EXPORT

Terzan said that 50 percent of his sales are exported, "When we look at the general trend, we observe that our export share has come from behind and slowly but surely started to exceed our domestic market sales."

NEGATIVE EFFECTS OF THE CHIP CRISIS CONTINUES

Talking about the effects of the epidemic on the economy, Terzan said, "It was an unexpected and difficult period." He said the following about the ongoing chip crisis and the activity in the economic markets:

“The fact that the epidemic was losing its effect in the economy and in other areas made everyone's hopes begin to bloom again as we saw. However, the raw material shortage that started during the pandemic and still continues, especially the chip crisis and cost fluctuations continue to have negative effects on us. This environment naturally causes us to frequently review our short-term goals and make various changes. But we continue to protect our medium and long-term goals. In particular, we are trying to prioritize European markets with high added value, where our products already have standard compliance and Liftinstituut approved certificates.”

Mik-el Elektronik, one of the most rooted control system manufacturers in the Turkish elevator market, and also gaining an important place in the sector with its many complementary products such as smart floor and car button boards and car position sensors, showcased its new products at the Interlift Fair held in Germany.

Answering the questions of Haber Asansörü at the Interlift Fair, Mik-el Elektronik Board Member and General Manager Nihat Güven announced that "Mini U-STO" will enter mass production soon and said that they are preparing for promotion.

CREATED OPPORTUNITY IN RESPECTABILITY

Making evaluations about Interlift Fair, Güven said:

“This year's Interlift has been much quieter than the previous ones. Many participants, including important companies, preferred not to take part in this fair. However, we can say that this situation created an opportunity for us to be noticed. Even though the number of visitors is below the usual level, we had the opportunity to have more effective conversations with the visitors.”

THERE IS STILL TIME FOR HIGH-SPEED ELEVATORS

Saying that they do not have significant differences with their global competitors in terms of technology level, Güven said, “However, technologies are used differently for target markets, of course. For example, the preferred -destination control- control method for very high stops, very fast and 4/6/6 lifts is not a priority for us for now. We need to use our R&D resources correctly and efficiently in line with our goals.”

Emphasizing that they have a sensitive approach to R&D studies, Güven said, “As the first company that brought this technology to the sector about 35 years ago, we have always given importance to R&D studies. We are able to develop products to meet the legislation and local demands of different markets, primarily the European market. In this way, we have a range of products suitable not only for Europe and the Middle East, but also for Asian and South American markets, and they are in constant development.”

HIGH CAPACITY PRODUCTION

“We have a production capacity of more than 10 thousand integrated elevator control/driver devices, more than 3 thousand elevator control panels, over 4 thousand elevator control card sets and a large number of accessory products such as smart button boards, car position sensors,” Güven said. line, high-definition optical quality control system, wave soldering system, manual soldering stations, many automatic test setups.

“WE HAVE BEEN A RELIABLE BRAND IN THE WORLD”

Guven stated that Mik-el Elektronik, which was established in 1988, is the first microprocessor-based electronic elevator control system manufacturer in Turkey to take place in the sector and said, "We have produced modern products by closely following the technology and constantly renewing the product portfolio. In addition to this, we have become a reliable brand with customers not only in Turkey but also in many different parts of the world, with our effective sales and after-sales support services.”

Talking about Mik-el Elektronik's service policy and development processes, Güven said, "Our services begin with our effective sales team, who aim to choose the right product in line with the customer's needs. It then continues with our production department, which includes strict quality control and traceability. At the last stage, our after-sales technical support unit provides our customers with a fast and effective commissioning and troubleshooting service.

MİK-EL ELECTRONICS SALES MANAGER EMRAH TERZAN: “OUR MINI U-STO PRODUCT SUPPORTS BETWEEN 4-7.5 KW, UP TO 1.6 M/S”

Mik-el Elektronik Sales Manager Emrah Terzan, who gave information about the new integrated elevator control system "Mini U-STO" exhibited at the fair, reminded that the compact structure of the "U-STO", which was introduced to the market before, was placed in a thinner body. Providing information about the technical details of the product, Terzan said:

“With Mini U-STO, it is a product that will serve elevators between 4-7.5 kW and up to 1.6 m/s cabin speed. Thanks to its compact structure, it enables the control panels to become smaller without sacrificing performance. Thus, we offer a very suitable solution for home lifts, which we call homelift, and modernization projects with space shortages.”

DIRECT EXPORT TO 30 COUNTRIES

Stating that they provide direct service to many customers in approximately 30 countries, Terzan said:

“Our products reach many more countries indirectly besides these countries. In order to protect and develop our portfolio, we first try to keep our relations with our customers warm. Customers who can reach us whenever they need, are happy and share their satisfaction with the companies around them, are more important than the most effective promotion for us to develop our export portfolio. We are also trying to provide our technical support service at the highest level.”

As the epidemic started to ease, we took our place in Elevator Istanbul, which was postponed to March 2022, and Interlift, which was postponed to April 2022, which are among the most important events of the industry. We had the opportunity to meet face-to-face with many new prospects and existing customers. These fairs are among the most beneficial events in terms of improving our targets in domestic and foreign markets.”

DESPITE THE PANDEMIC, OUR PORTFOLIO EXPANDED

Emphasizing that the pandemic period created various obstacles to the realization of sectoral organizations, Terzan said, "Even during this period, we managed to improve our business volume with some of our existing customers and add some new export customers to our portfolio."

Terzan mentioned that they have export customers with whom they have been working for more than 20 years and said, “This is a very satisfying picture for us in terms of the work we do. Of course, we certainly do not see this as a reason for complacency. On the contrary, we are aware that this will be sustainable by continuing to work hard and always being able to stay in warm contact with our customers.”

50 PERCENT EXPORT

Terzan said that 50 percent of his sales are exported, "When we look at the general trend, we observe that our export share has come from behind and slowly but surely started to exceed our domestic market sales."

NEGATIVE EFFECTS OF THE CHIP CRISIS CONTINUES

Talking about the effects of the epidemic on the economy, Terzan said, "It was an unexpected and difficult period." He said the following about the ongoing chip crisis and the activity in the economic markets:

“The fact that the epidemic was losing its effect in the economy and in other areas made everyone's hopes begin to bloom again as we saw. However, the raw material shortage that started during the pandemic and still continues, especially the chip crisis and cost fluctuations continue to have negative effects on us. This environment naturally causes us to frequently review our short-term goals and make various changes. But we continue to protect our medium and long-term goals. In particular, we are trying to prioritize European markets with high added value, where our products already have standard compliance and Liftinstituut approved certificates.”